Press-type Fitting (for copper)

Product summary

In Japan, since its release in 1989 as a fitting for copper pipes for piping system. The features that do not require the use of fire are evaluated, which is inevitable in conventional construction methods, and many achievements have been made in hot water supply pipes in chalets.

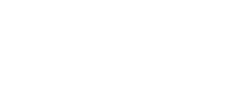

Structure

A heat-resistant rubber ring is attached to the fittings bead at the end of the copper fittings. By installing a core*1*2 to enhance the pull-out strength, inserting pipe *3 into the appropriate position, and press by specific tool, the efficiency of keeping water tightness, durability and sufficient altitude can be increased.

*1 When using the copper pipe type M for pipeline construction, please be sure to install the in-core.

*2 For 10A bare pipe do not have an in-core.

*3 Copper pipes for construction type M, type L, type K, material H, material O.

Scope

● Compatible: Copper pipe (JWWA H101, JIS H3300, JIS H3330)

● Usage: Water/ hot water, cold water, coolant water, cold/hot water and others.

*Not suitable for steam piping

● Operating pressure: 1.0MPa(10.2kgf/cm2)

● Operating pressure: Under 80℃

● Water quality standards: Tap water must comply with “Water quality standards according to The Ministry of Water Supply as Section 4 of Water Works Law. CU press can be used for water plumbing supply if verified to meet “Water quality standards as the Ministry of Water Supply Standards”.

Please contact us if you use in the following cases

① Water supply pipeline: When not meeting the "Water quality standards as prescribed by the Ministry of Water Quality Standards".

② Hot water supply pipeline: When not meeting the "Water quality standards as prescribed by the Ministry of Water Supply Standards".

Installation