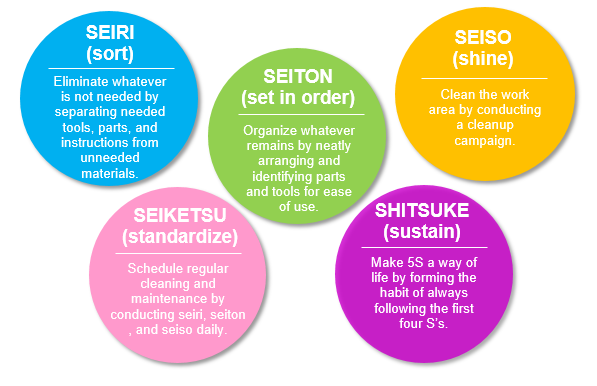

Organization “5S activities”

Related news

17/07/2024

1. Mechanical

Metal machining can be divided into two types: machining that removes material and machining that does not remove material.

Machining without material removal is processing that does not generate metal debris such as casting, welding, and pressing.

On the contrary, material removal machining methods are machining methods that generate metal debris (Chips) such as cutting and grinding machining.

Material removal machining often uses equipment such as Lathes, Milling Machines,...

18/07/2024

■Standardization

As a business develops, standards for quality, performance, safety, dimensions, testing methods, etc. are essential.

Standards are a collection of common rules (arrangements) called "standardization" that have been established.

The purpose is to "reduce, simplify, order, and unify things and matters that would otherwise become diverse, complex, and disordered if left alone."

First, each company will conduct internal standardization.

However, if each company works according to its...

11/07/2024

What is piping…

Piping is a system of pipes that convey fluids (liquids and gases) from one location to another by comprehensively designing pipes, fittings, etc.

When we think of liquids and gases, we think of water and air, but some pipes flow special fluids. Among them, when it is called general piping, means piping that is directly connected to people's lives, such as water supply, hot water supply, or air conditioning piping.

Piping is so essential to people's daily lives that it is...

18/07/2024

① What is stainless steel?

Stainless steel is known as INOX in Vietnam.

Stainless means "not rusty".

Strictly speaking, it also includes the meaning of "resistant to rust."

Stainless steel is a rust-resistant alloy whose main component is iron (Fe) (over 50%) and chromium (Cr) over 10.5%, and its usage is rapidly increasing compared to other materials.

The increase in the amount of stainless steel used is thought to be due to the material's excellent properties, which are expanding its...

11/07/2024

What is stainless steel...

Stainless steel is used in many things around us these days, and I think many of you are familiar with it.

However, although stainless steel has become a part of our daily lives, it is a metal with a relatively short history.

I think there are very few people who can answer specifically what stainless steel is.

"stainless steel" is a "rust-resistant steel" with excellent corrosion resistance, but at the same time, it is not something that will ever rust.

Stainless...

16/07/2024

What is quality?

The manufacturing industry consists of processing raw materials to produce and provide products desired by customers.

Quality is important.

Quality is the inherent performance of a product and its fulfillment.

On the other hand, if the quality is not present, the product will not match the customer's needs.

In that case, the business will not be viable.

Therefore, in the manufacturing industry, quality assurance is important, and it can be said to be the core part of...

17/07/2024

1. Pouring Casting Processing

Metal processing methods are divided into two main categories: material removal processing and non-material removal processing.

Machining without material removal is processing that does not generate metal debris such as casting, welding, and pressing.

On the contrary, the material removal machining method is a machining method that generates metal scraps (Bavia) such as cutting and grinding machining.

At BENKAN VIETNAM, we do not limit any processing methods,...

19/07/2024

1. After-sales management

Benkan Vietnam is a unit specializing in manufacturing and trading mechanical joints for stainless steel pipes.

And our priority is quality management.

The products that Benkan Vietnam provides are not just finished products when shipped.

Only when our products are used by customers for installation does it become a finished product.

Therefore, in total quality management (TQM: Total Quality Management), we have three major management systems.

Source Control means...

20/07/2024

1.Thread standards

One of the typical connection methods for pipes is the "thread" connection.

Its characteristic is that due to its spiral structure, there are two main types: male screws with threads on the outside and female screws with threads on the inside, used to connect parts.

Benkan Vietnam also has many product lines that come with "screws".

However, "thread" also has two types of "male thread": "R (taper male thread for pipes)" and "G (parallel male thread for pipes)". For "female...

20/07/2024

1. What is piping?

"Piping" is defined at Bencan as "a system that appropriately delivers fluids such as liquids and gases to the target location by designing equipment and equipment such as pipes, fittings, and valves in a comprehensive manner."

Its uses are very varied, and depending on the position, it can be interpreted in a variety of ways.

For example, in the case of water supply pipes in houses, they are a natural part of human life, and as they are also called lifelines, they are...